Shell and Tube Heat Exchanger | Types of Heat Exchanger | Different Types of Heat Exchanger

In this article today, we will talk about Shell and Tube Heat Exchanger, and we will know what are the types of heat exchanger used in our refinery i.e. oil and gas field, so first we will talk about the definition of heat exchanger. What is an exchanger called?

|

Types of Heat Exchanger |

Whatever your confusion today is that by taking the heat exchanger it will be absolutely clear and after that there are any problems, then you tell us in the comments below so let’s start with what is the definition of heat exchanger.

Definition of Heat Exchanger

A heat exchanger is an equipment which is built for efficient heat transfer from one medium to another i.e. A heat exchanger is an instrument that is designed in such a way that the transfer of the heat takes place from one medium to another, the media may be separated by a solid wall so that they never mix.

Watch Video

Basic Intoduction of Heat Exchanger

After the introduction, we now know a little bit about where the heat exchanger is used, the heat exchanger is used for the Space heating, Refrigeration, Air conditioning, Power plant, Chemical plant, Petrochemical plant, Natural gas processing and for Sewage treatment It is also used for.

Types of Heat Exchanger

So let’s talk a little bit about what type of heat exchanger you have. You don’t have to be confused at all about the types of heat exchanger. Mainly, there are four types of heat exchanger we use.

1. Shell and Tube Type Heat Exchanger –

Shell and tube type heat exchanger is a type of heat exchanger that is most commonly used in oil and gas field refineries and it is most used for high pressure applications.

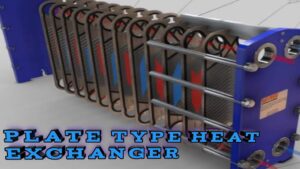

Plate Type Heat Exchanger

3. Air cooled Type Heat Exchanger –

The most commonly used heat exchanger after any shell and tube type heat exchanger inside any oil and gas or refinery is the air cooled i.e. fan-fan type heat exchanger. These units are used to cool and /or condense process streams with ambient air cooling medium instead of water.

|

Air cooled or fin-fan type heat exchanger |

4. Double pipe Type Heat Exchanger –

A double pipe heat exchanger may be a very basic arrangement where two fluids can exchange heat without coming in touch with each other . It consists of two pipes. The smaller diameter pipe is places inside the pipe like concentric circle. The two fluids flows through the inner pipe and thru the annular area. Usually the warmer fluid flows through the inner pipe.

This kind of warmth exchanger is typically used where very less heat transfer area is required or where the pressure drop across the heat exchanger should be kept minimum.

Now shell and tube type heat exchanger is divided into four parts so that is explained closely in the video above, so click on the video above to understand the parts of shell and tube type and easily Watch the video if you want us to write the shell and tube type classifications here, then tell us in the comment box below.

Thank you

Pingback: HEAT EXCHANGER WORK-SCOPE FOR SHUTDOWN - SoNu SiNgH Refinery

Pingback: HEAT EXCHANGER WORK-SCOPE FOR SHUTDOWN → SoNu SiNgH Refinery

Pingback: HEAT EXCHANGER WORK PROCEDURE FOR SHUTDOWN - Download 5 Free PDF

Pingback: What is Rupture Disk - Download 5 Free PDF

Pingback: Centrifugal Pump Interview Questions and Answers - Download 5 Free PDF

Pingback: The Best ITI Courses After 12th in India [2024] : A Guide for Boys and Girls

Pingback: How to Find Overseas Jobs in India

Sir need pdf file of heat exchangers

Pingback: How to read Piping and Instrumentation Diagrams (P&ID): Top 4 Best Practices - PIPING PDF

Pingback: What is Non-Destructive Testing (NDT)

Pingback: Double Block and Bleed Valves

Pingback: Fitter Full Form

Pingback: High Pressure Valves

Pingback: Understanding Pipe Fitting Standards

Pingback: Understanding uPVC Pipes: Free Guide with Prices

Pingback: Back Pressure Regulator : Top 4 Benefit Hack

Pingback: NDT - What does Non-Destructive Testing (NDT) mean: Top 5 best methods of NDT

Pingback: Pipe OD, ID, Circumference, NPS, DN, NB, THK, and SCH Explained

Pingback: Heat Exchanger Gasket Types, Names and Materials