Pipe OD, ID, Circumference, NPS, DN, NB, THK, and SCH. Explained with Examples

Pipe ! In the world of piping systems, understanding the technical specifications and measurements is critical for the success of any project. Whether you’re working in the oil and gas industry, manufacturing, construction, or any other sector that involves piping systems, you’ll often come across terms like Pipe OD (Outside Diameter), ID (Inside Diameter), Circumference, NPS (Nominal Pipe Size), DN (Diameter Nominal), NP (Nominal Pressure), THK (Thickness), and SCH (Schedule). Each of these terms plays an essential role in determining the specifications and applications of pipes. This article will break down each of these terms in detail, providing real-world examples to help you grasp their significance and how they interrelate.

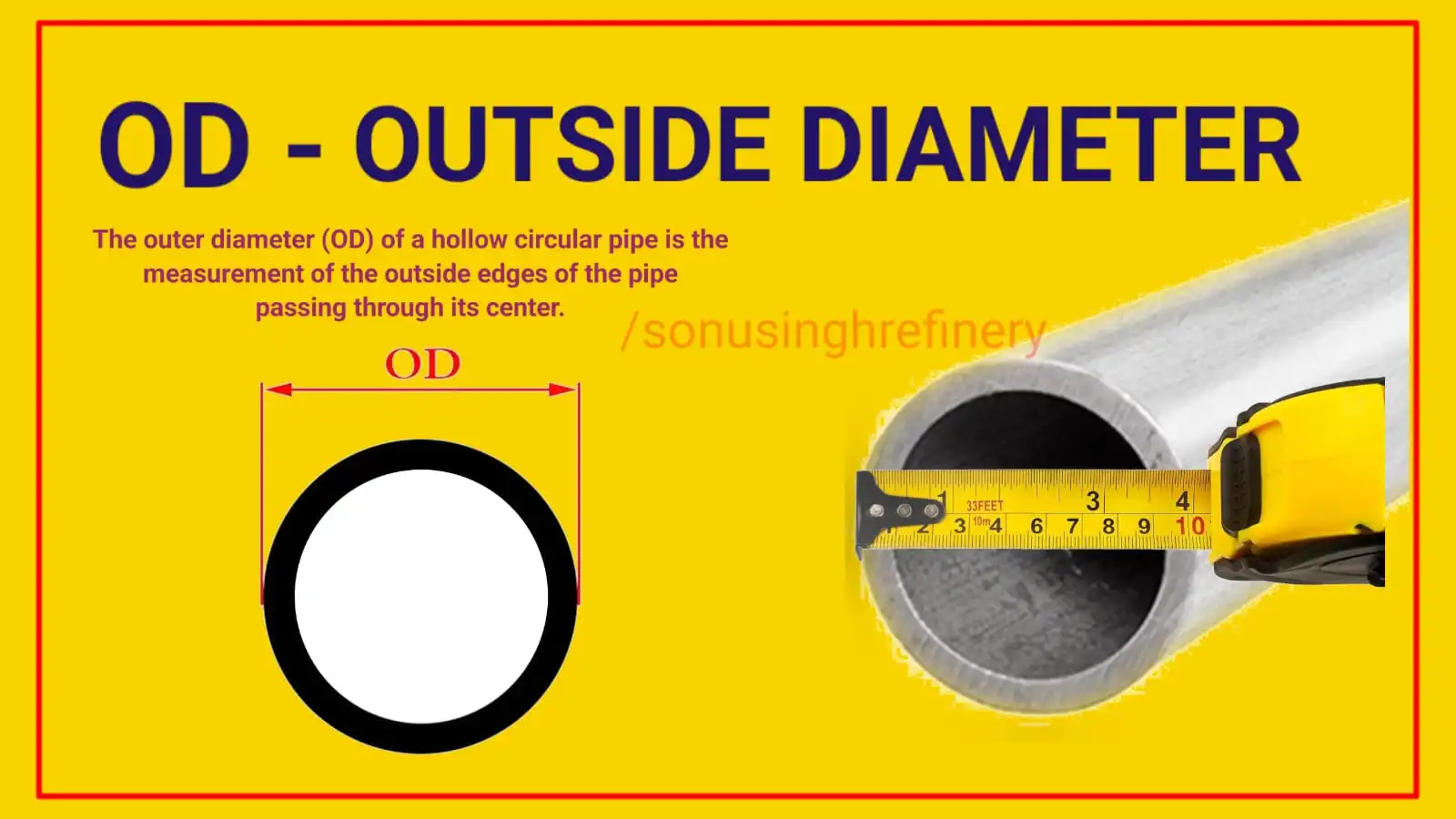

Pipe OD (Outside Diameter)

The Outside Diameter (OD) of a pipe refers to the distance across the outermost edge of the pipe. This measurement is crucial because it helps determine how much space the pipe will occupy. OD is also vital for calculating wall thickness, pressure capacity, and how the pipe will connect to other piping or components such as fittings and valves.

Example: If you have a pipe with an OD of 4 inches, this means that the total width of the pipe from one outer edge to the opposite outer edge is exactly 4 inches. The OD remains consistent for a specific type of pipe, regardless of its wall thickness or schedule.

OD is usually constant for specific pipe sizes, and it’s measured using calipers or measuring tape, depending on the scale of the pipe.

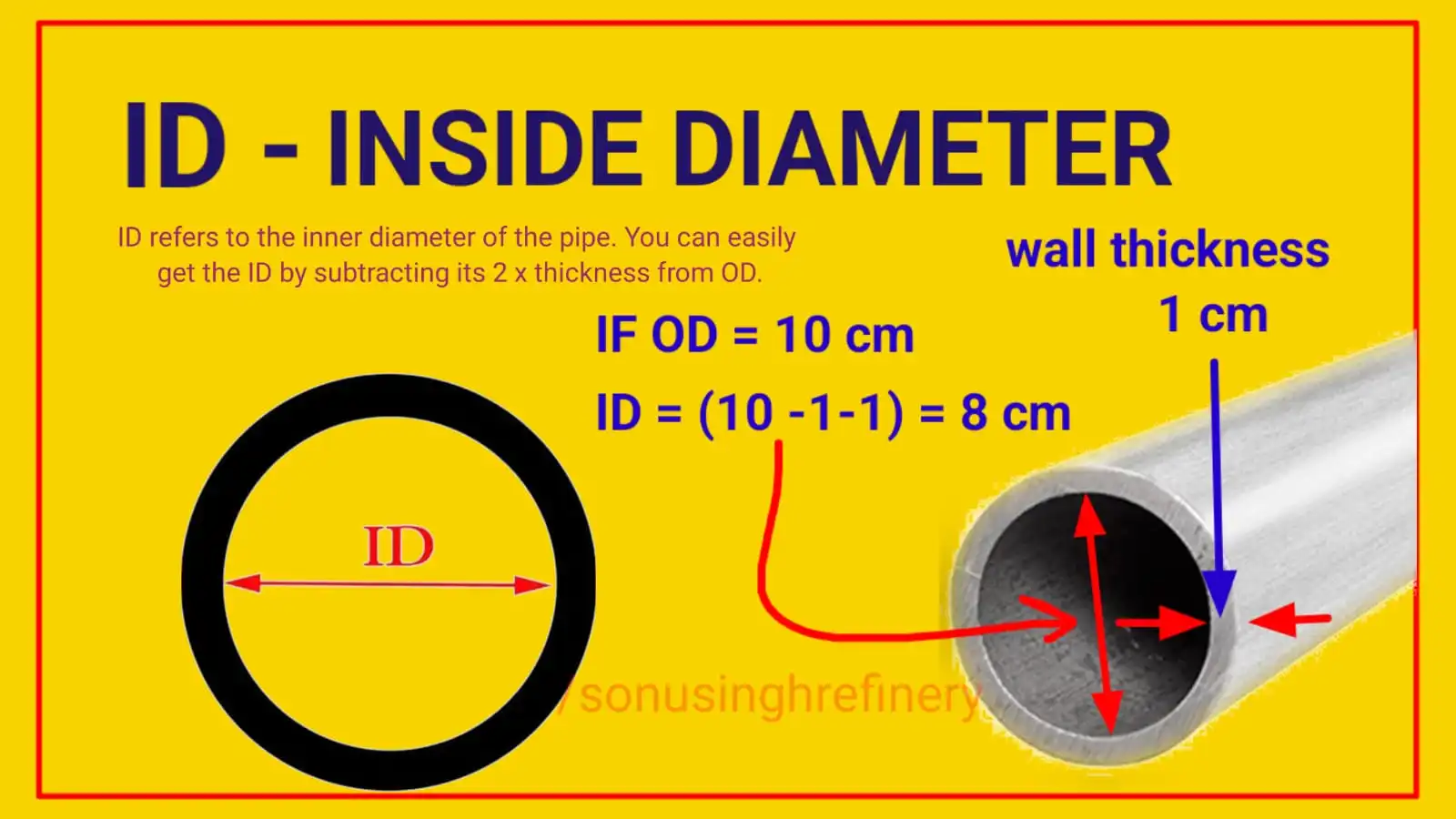

Pipe ID (Inside Diameter)

The Inside Diameter (ID) is the distance between the inner walls of the pipe. The ID is critical because it determines the flow capacity of the pipe. This is especially important in fluid flow applications, as the larger the ID, the more fluid the pipe can carry.

Example: For a pipe with an OD of 4 inches and a wall thickness of 0.5 inches, the ID would be calculated as: ID=OD−2×Wall Thickness

In this case: ID=4−2×0.5 = 3 inches

The ID becomes smaller as the wall thickness increases, even if the OD remains the same. This is why understanding both OD and ID is important when choosing pipes for your system.

Pipe Circumference

The circumference of a pipe is the total distance around the pipe’s outer edge. It is calculated using the formula: Circumference=π×OD Circumference is significant when you’re wrapping insulation around a pipe or determining the total material needed for coatings or external treatments.

Example: If a pipe has an OD of 6 inches, the circumference would be: Circumference=π×6 = 18.85 inches

Knowing the circumference is also useful for calculating things like pipe weight and surface area for coating or insulation

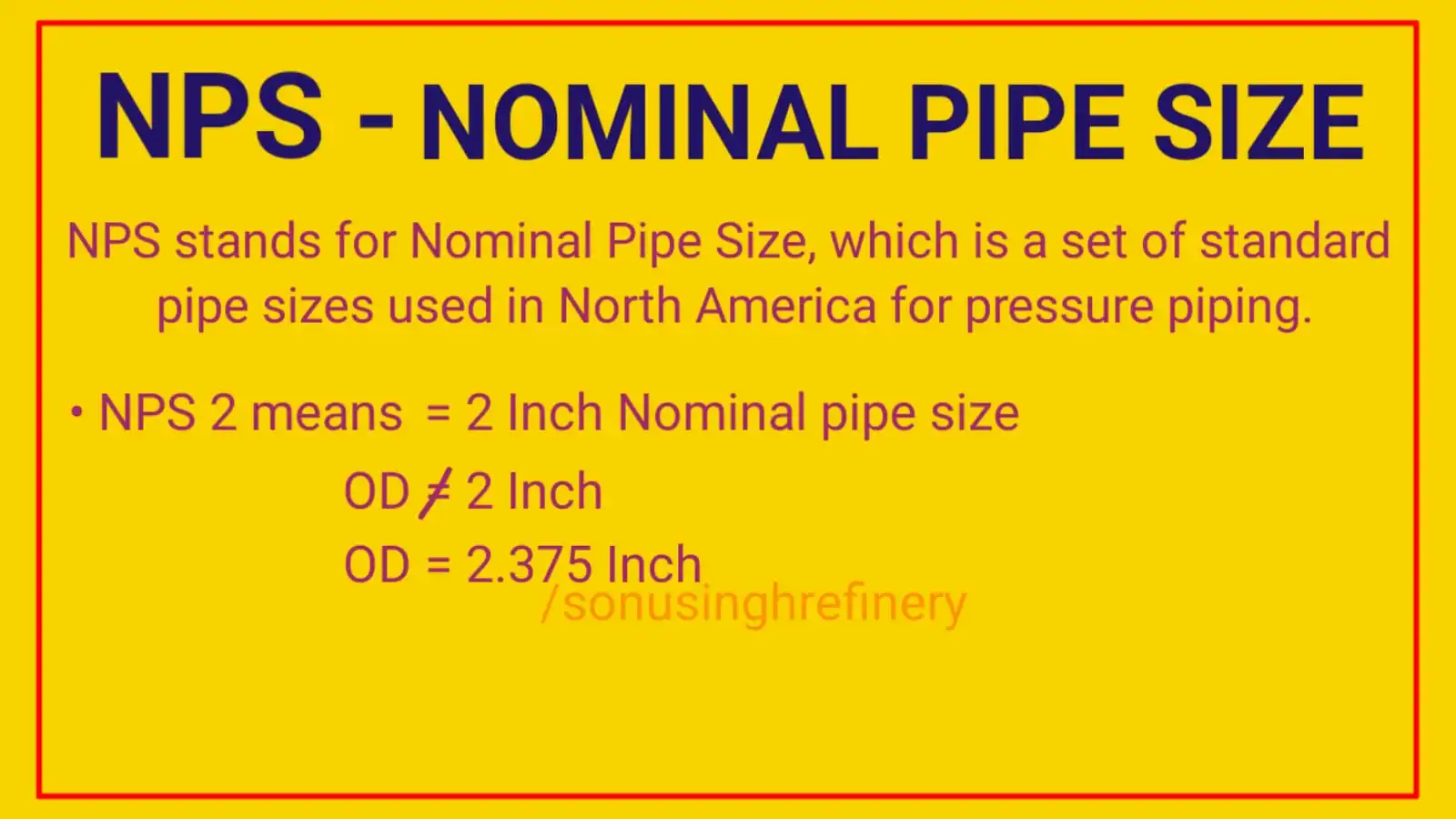

Pipe NPS (Nominal Pipe Size)

NPS stands for Nominal Pipe Size and is a standardized size designation that represents the approximate size of the pipe. However, it is important to note that the NPS does not always correlate exactly with either the OD or the ID. NPS is more of a “nominal” value used to standardize pipe sizes for fittings, connections, and other specifications. It is primarily used in North America.

Example: A pipe with an NPS of 2 inches does not mean the pipe’s OD is exactly 2 inches. In reality, the OD of an NPS 2 pipe is 2.375 inches.

NPS is crucial when selecting pipe fittings and other components, as these components are typically made to match the NPS designation, not the precise OD or ID.

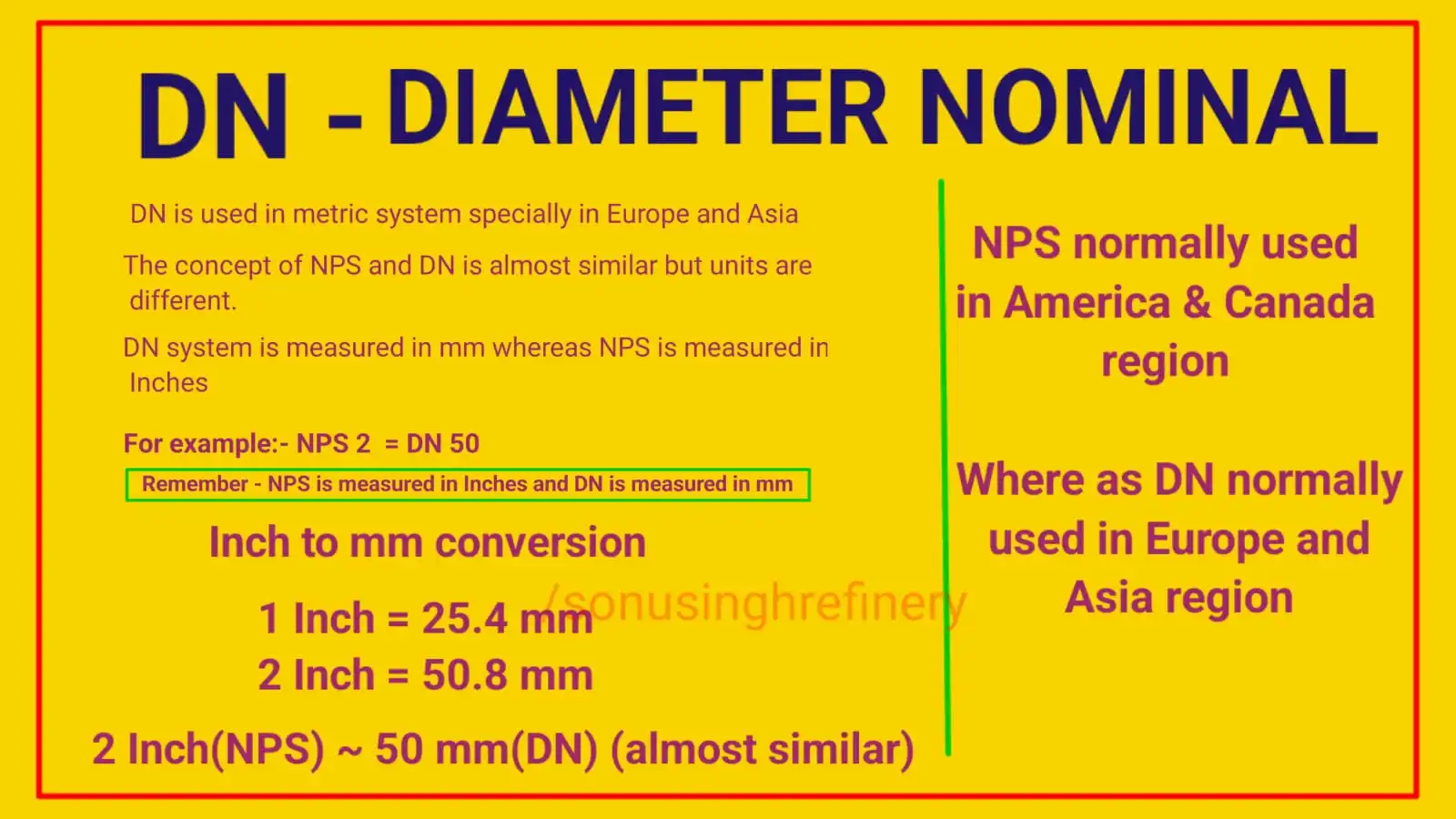

Pipe DN (Diameter Nominal)

DN, or Diameter Nominal, is the metric equivalent of NPS and is commonly used outside of North America. Unlike NPS, which uses inches, DN uses millimeters as its unit of measurement. DN also serves as a nominal size and doesn’t exactly correspond to the pipe’s OD or ID, similar to NPS.

Example: A pipe with a DN 50 has a corresponding NPS of 2 inches, but the actual dimensions may vary. DN is especially important in European and Asian markets where the metric system is dominant.

DN helps provide a standardized reference across international markets, ensuring that piping systems are compatible regardless of where they are manufactured or installed.

Pipe NB (Nominal Bore)

NB, or Nominal Bore, is another term used primarily in the UK and India to describe the approximate inside diameter (ID) of a pipe. Much like NPS (Nominal Pipe Size), NB serves as a standard designation for pipe sizes and is used interchangeably with NPS in many regions. However, while NPS is more commonly used in North America, NB is favored in other parts of the world.

The key thing to remember is that NB does not represent the exact measurement of the pipe’s ID but instead serves as a reference or nominal size. It’s an approximate value that helps standardize pipe sizes for compatibility with fittings, flanges, and other piping components.

Example:

A 2-inch NB pipe will have an ID that is close to, but not exactly, 2 inches. The actual inside diameter may be slightly smaller depending on the pipe schedule (SCH), which dictates the wall thickness (THK) of the pipe.

How NB Relates to NPS and DN

While NB and NPS are often used interchangeably, the difference in terminology can cause confusion, especially when working internationally. NPS is more prevalent in the US and Canada, while NB is used in the UK, India, and other regions following British standards. DN (Diameter Nominal), on the other hand, is the metric equivalent and is commonly used in European and Asian countries.

Example:

- NB 50 is equivalent to NPS 2 inches or DN 50 in the metric system.

- The actual measurements of the pipe might differ slightly, but the NB, NPS, and DN systems all provide a standardized reference for sizing.

So, NB serves as a simplified way to reference the inside diameter of pipes, especially in markets outside of North America. It’s crucial to understand the NB designation when working on international projects to ensure compatibility and accurate pipe selection.

Pipe NP (Nominal Pressure)

NP stands for Nominal Pressure, which defines the maximum pressure a pipe can withstand under normal operating conditions. This is a critical factor in industries where pipes are used to transport liquids or gases under pressure, such as in oil refineries, power plants, or chemical processing units.

Example: A pipe with NP 16 can handle a pressure of up to 16 bars, which is a common pressure rating for industrial applications.

Understanding the NP of a pipe is essential for ensuring the safety and reliability of a system, especially in high-pressure environments.

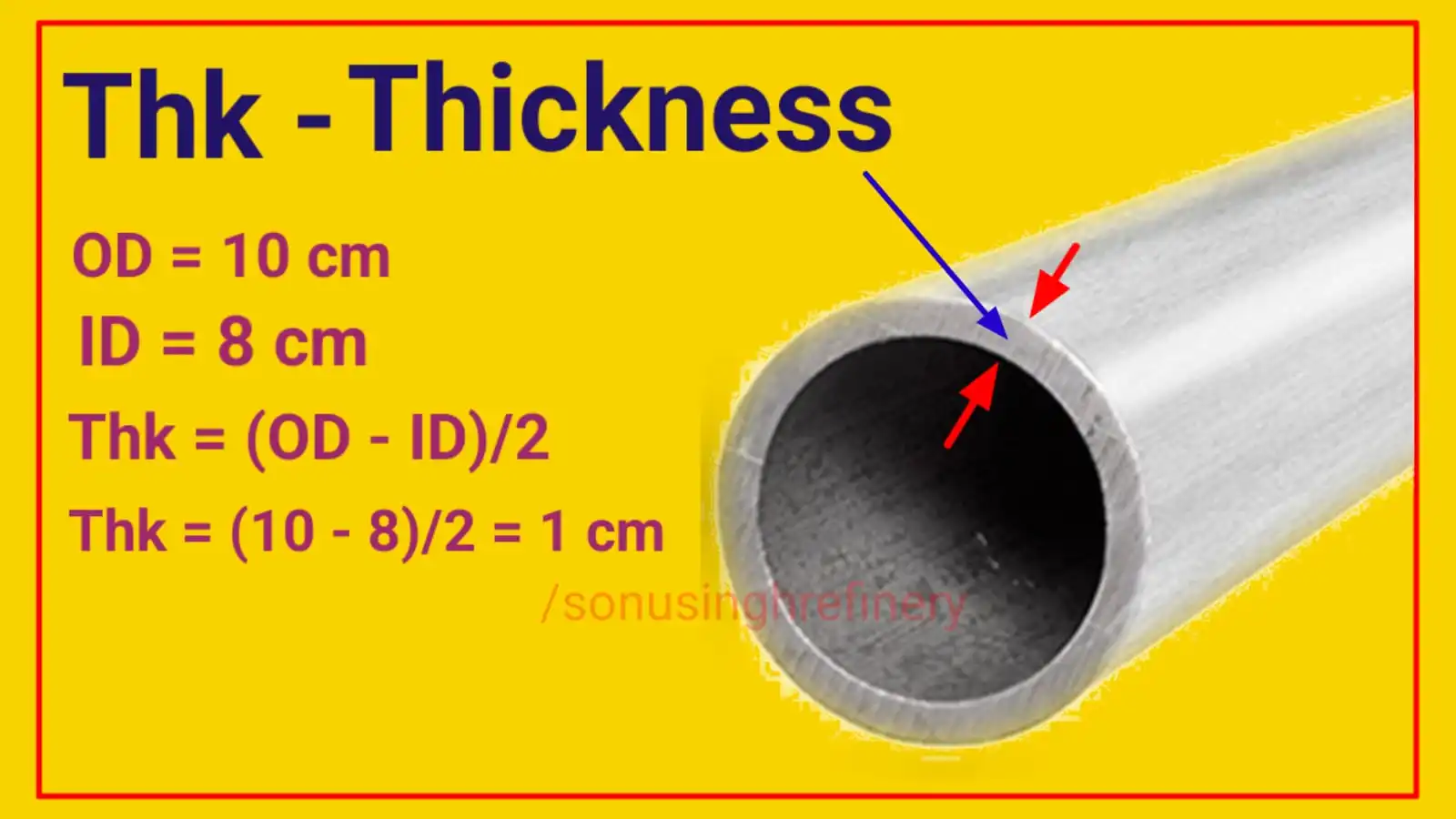

Pipe THK (Wall Thickness)

Wall Thickness (THK) refers to the thickness of the pipe’s wall and is a critical parameter for determining the pipe’s strength, durability, and flow capacity. Thicker walls mean greater resistance to pressure, but also reduce the ID and, consequently, the flow capacity of the pipe.

Example: If a pipe has an OD of 6 inches and a wall thickness of 0.5 inches, the ID would be: ID=6−2×0.5=5 inches

Selecting the right wall thickness depends on the operating pressure, temperature, and the type of fluid being transported.

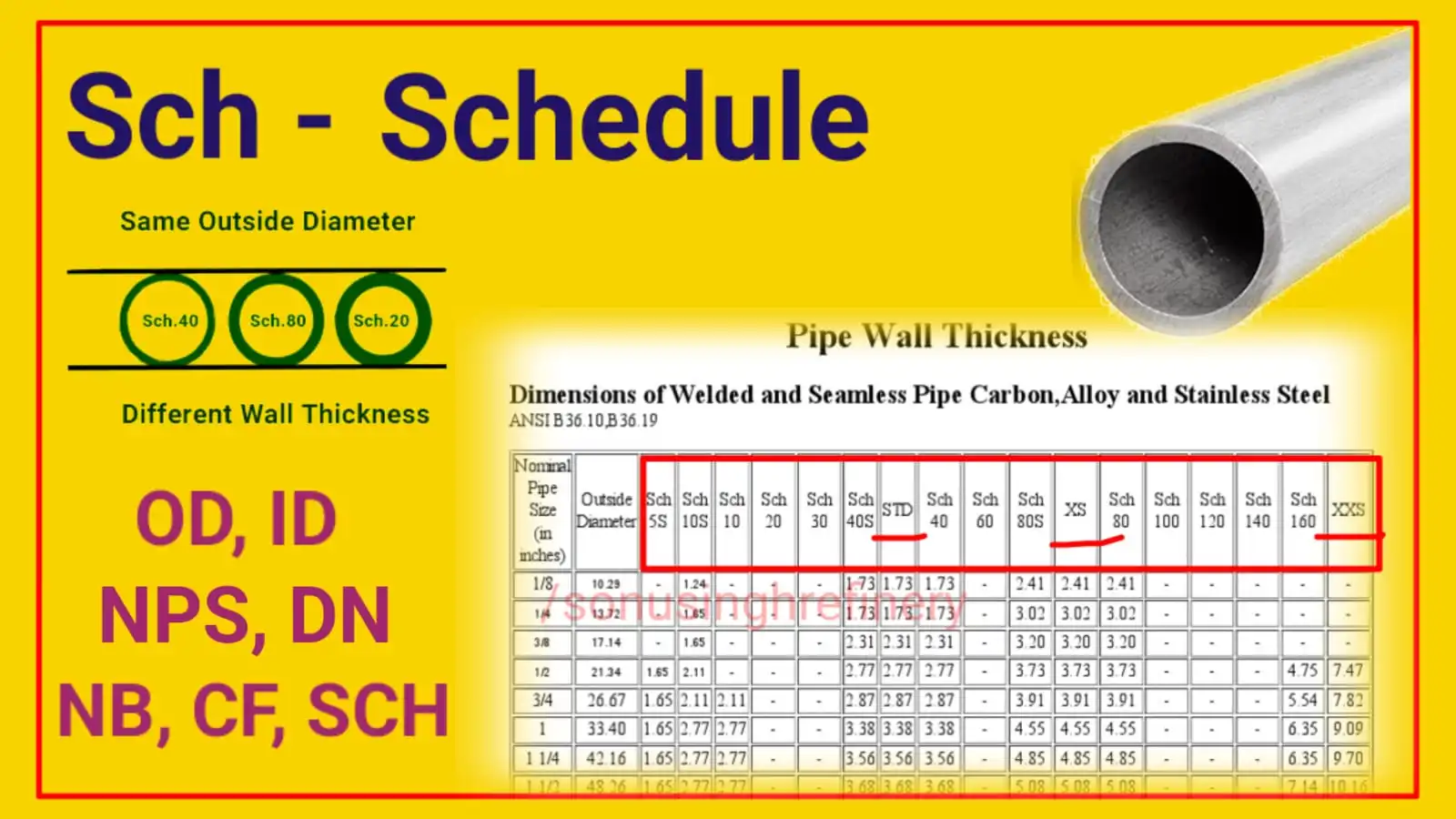

Pipe SCH (Schedule)

Pipe Schedule (SCH) is another term that refers to the wall thickness of a pipe. Different schedules have different thicknesses, and higher schedule numbers indicate thicker walls. For example, SCH 40 is a commonly used pipe schedule, but as you go up to SCH 80 or SCH 160, the wall thickness increases, making the pipe suitable for higher pressure applications.

Example: A 2-inch NPS pipe with SCH 40 has a wall thickness of 0.154 inches, but the same NPS 2-inch pipe with SCH 80 has a wall thickness of 0.218 inches.

The schedule directly impacts the pipe’s pressure rating and is critical in applications where the pipe is subjected to high pressures or corrosive environments.

How OD, ID, SCH, and THK Work Together

When selecting a pipe for any application, understanding how OD, ID, THK, and SCH interrelate is crucial. While the OD remains constant for a given NPS pipe size, the ID decreases as the wall thickness (THK) increases with higher schedules (SCH).

For instance, a 2-inch NPS pipe will always have an OD of 2.375 inches, but the ID will vary depending on the wall thickness. A Schedule 40 pipe will have a thinner wall and larger ID compared to a Schedule 80 pipe.

This relationship is essential when calculating fluid flow, pressure ratings, and selecting appropriate pipe fittings.

Choosing the Right Pipe Specifications

When choosing a pipe for a specific application, understanding all these factors – OD, ID, NPS, DN, NB, THK, and SCH – is vital. For high-pressure systems, thicker pipes with higher schedules may be necessary, while systems focused on maximizing flow capacity may prioritize a larger ID with a lower schedule.

Example: In an industrial plant transporting highly corrosive chemicals at high pressure, you might choose a 2-inch NPS pipe with SCH 80 for its thicker wall and higher resistance to pressure and corrosion. However, in a low-pressure water supply system, a Schedule 40 pipe might suffice, offering a better balance between cost and capacity.

Conclusion

In summary, understanding the technical terminology surrounding pipes—OD, ID, Circumference, NPS, DN, NP, THK, and SCH—is essential for selecting the right pipes for any project. Each of these factors plays a crucial role in determining the pipe’s suitability for a given application, whether it’s industrial piping, water supply, or gas transport.

Proper knowledge of these terms ensures the reliability, safety, and efficiency of piping systems in any industry.

Read Also

Download Free Piping PDF for Interview Preparation

Download Free Piping PDF for Interview Preparation

What is gasket and their types

What is a valve and its types?