What is Lincoln Tech Welding School

Lincoln Tech Welding is well-known for its thorough and practical approach, which gives students a strong foundation in welding procedures and methods. Students study a variety of welding techniques, including stick welding, MIG, TIG, and more, via a combination of classroom instruction and hands-on training. The program aims to impart competence in welding equipment operation, metallurgical comprehension, and blueprint interpretation. Students learn critical skills in metal preparation, welding application, and safety procedures from knowledgeable teachers in a variety of sectors. Lincoln Tech places a strong emphasis on hands-on learning, giving students access to cutting-edge facilities and industry-standard welding equipment.

This curriculum develops problem-solving skills, critical thinking, and teamwork in addition to technical proficiency. Lincoln Tech welding program graduates frequently join the profession well-prepared, having acquired the information and abilities needed to succeed in the challenging welding industry.

What are Lincoln Tech welding Eligibility Criteria?

There are specified requirements for admission to Lincoln Tech’s welding programs. Lincoln Tech is a well-known vocational school that offers programs in a variety of technical subjects. To be eligible to register for Lincoln Tech’s welding courses, prospective students usually have to fulfill specific requirements. Typically, applicants should have a high school degree or its equivalent, as well as demonstrate a foundational understanding of arithmetic and reading skills. To evaluate candidate’s enthusiasm, dedication, and aptitude for welding, they may also be asked to participate in an admissions interview.

Although prior welding expertise is not required for admission, it is highly recommended to have a strong love for the craft and a willingness to learn. Lincoln Tech places a strong emphasis on commitment, self-control, and a sincere desire to pursue a welding profession. Admission to their welding courses may also involve fulfilling any other program-specific conditions, such as age limitations or physical fitness requirements. The overall goal of Lincoln Tech’s eligibility requirements is to guarantee that prospective welders possess the fundamental abilities and commitment required to succeed in their education and ensuing employment in the welding sector.

What are Lincoln Tech welding fees?

Lincoln Tech is a well-known college that provides a range of career programs, including welding. The cost of the welding program at Lincoln Tech varies depending on several variables. Usually, the pricing structure covers tuition, supplies, and any other costs that may arise. Depending on the length of the program and the location, Lincoln Tech’s welding tuition might cost anywhere from a few thousand to over $20,000. Essential supplies including safety clothing, welding equipment, teaching materials, and access to the workshops and labs are all covered by the costs. In addition, there may be other expenditures related to the program, such as books, registration fees, and miscellaneous charges.

For the most up-to-date and correct information on welding program prices, prospective students should visit Lincoln Tech’s official website or get in touch with them directly. This is because costs can change over time and between different campus locations. Furthermore, students may be eligible for grants, scholarships, or financial aid to help defray part of the costs related to the welding program.

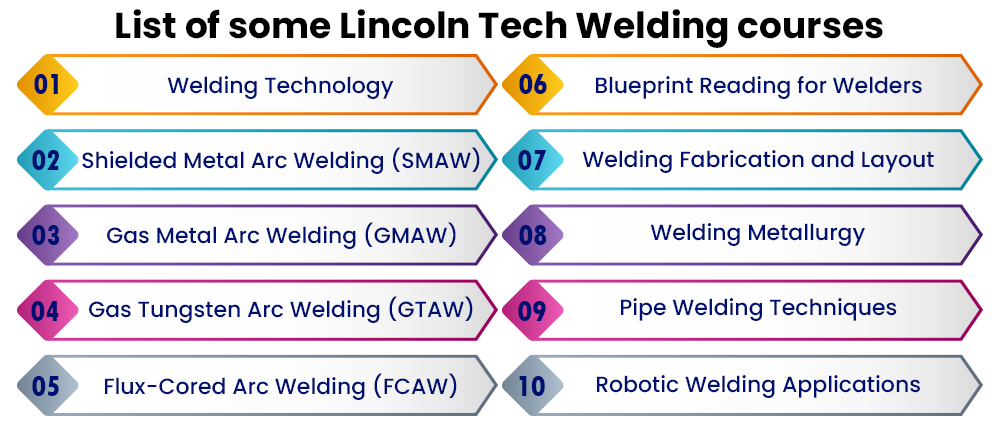

What is the Lincoln Tech Welding course?

The Lincoln Tech Welding course is a thorough and specialized curriculum created to provide students with the abilities and information needed to succeed in the welding industry. This course, which is designed by Lincoln Tech, a well-known technical education school, usually includes a broad range of welding methods, safety precautions, and industry-standard procedures. With an emphasis on both academic understanding and practical application, the course framework helps students become proficient through simulations and real-world projects.

Furthermore, to guarantee that graduates are equipped to meet the expectations of the workforce, Lincoln Tech’s welding program frequently incorporates cutting-edge technology and industry-standard instruments. The program’s goal is to develop competent welders who can satisfy the unique demands of a variety of industries, including the industrial, construction, automotive, and aerospace sectors. It does this by emphasizing safety, precision, and workmanship. After completing the program successfully, graduates usually gain useful skills and certifications, enabling them to pursue fulfilling jobs as certified and skilled welders in the competitive labor market of today.

Lincoln Tech Welding Program reviews

Reviews of the Lincoln Tech Welding Program are mixed, representing a wide range of viewpoints and experiences from previous participants. Numerous people applaud the program for its extensive curriculum, knowledgeable teachers, and experiential learning methodology. Students frequently emphasize the program’s focus on hands-on learning, which gives them a solid foundation in a variety of welding methods, safety precautions, and industry-relevant skills. Positive comments are also given regarding the availability of state-of-the-art facilities and equipment, which allow students to work with cutting-edge machinery and real-world welding scenarios.

On the other hand, some evaluations express issues with the program’s speed, implying that the coursework may be demanding and demanding for some students. Furthermore, even while a large number of students praise the caliber of education, others voice discontent with certain teachers or administrative features. Based on personal viewpoints and expectations, the Lincoln Tech Welding Program seems to provide a solid educational experience overall, however, there is potential for improvement. Prospective students might find it helpful to take into account these differing assessments when determining if the program is a good fit for their preferred learning style and professional aspirations.

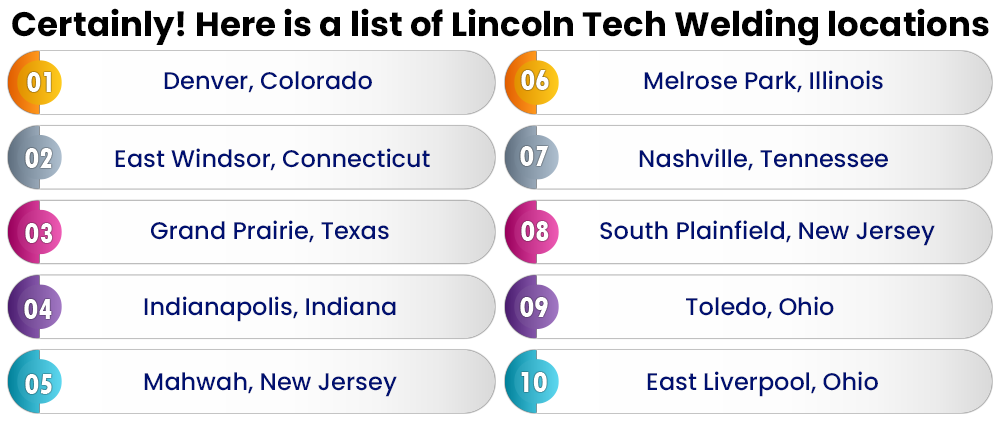

Lincoln Tech Welding locations

Comprehensive welding programs are available at numerous campuses around the United States of Lincoln Tech, a well-known vocational training institution. These facilities are carefully positioned to serve prospective welders who are looking for excellent instruction and practical experience. There are many locations for the Lincoln Tech Welding program, including but not limited to Grand Prairie, Texas; Denver, Colorado; East Windsor, Connecticut; Indianapolis, Indiana; and Nashville, Tennessee. Every school has state-of-the-art facilities, cutting-edge equipment, and knowledgeable instructors committed to giving students a comprehensive education in industry-specific skills, safety procedures, and welding methods.

These places operate as centers where students may fully engage in hands-on instruction and learn a variety of welding techniques, including stick, MIG, TIG, and pipe welding. Additionally, Lincoln Tech’s welding programs frequently work with business partners to provide internships, help with job placement, and exposure to real-world projects, all of which improve students’ preparation for a market that is very competitive for welding jobs. These varied establishments serve prospective welders around the country, guaranteeing accessibility and high-quality instruction for people who are enthusiastic about a welding vocation.

Lincoln Tech Welding Program length

The extensive and in-depth curriculum of the Lincoln Tech Welding Program is intended to provide students with the knowledge and abilities needed for a successful career in welding. The program’s duration varies according to the courses and learning pathways that each student selects. Prospective welders can choose from a variety of choices offered by Lincoln Tech, including both short-term courses and longer programs lasting several months.

For basic courses, the length might be as little as a few weeks; for more advanced and comprehensive programs, it can be as long as nine or twelve months. These programs make sure students understand basic welding skills, safety procedures, blueprint reading, metallurgy, and welding technologies by combining classroom education, hands-on practical training, and real-world experiences.

Lincoln Tech also provides students with a strong foundation to pursue a variety of career routes in welding, fabrication, construction, manufacturing, and other related sectors since its curriculum frequently complies with industry requirements. Throughout the program, students will have the opportunity to get a thorough understanding of several welding procedures, including MIG, TIG, Stick, Flux-Cored Arc Welding, and other specialized methods. This will provide them with the necessary expertise and confidence to succeed in the welding industry.

Piping Question Answer Series Part – 03

Download Piping Question Answer series Part – 04

Read Also

Download Free Piping PDF for Interview Preparation

What is gasket and their types

What is a valve and its types?

Other Videos you can watch click on below link

Refinery, Shutdown, Maintenance, Oil & Gas, Piping: ![]() • Refinery, Shutdown, Maintenance, Oil …

• Refinery, Shutdown, Maintenance, Oil …

Piping Related Videos: ![]() • Piping Related Videos

• Piping Related Videos

Complete Heat Exchanger: ![]() • Complete Heat Exchanger

• Complete Heat Exchanger