Introduction

Demister pad is a device used to remove small liquid droplets from a gas stream. They are similar to air filters, but more efficient at removing smaller particles. Demister pads are commonly used in process piping applications to protect downstream equipment from fluid ingress, which can cause rust, corrosion, and other problems.

History of demister pad

In the late fifties, foreigners used a device made of special wrinkled woven mesh to remove small liquid foam inclusions in the gas. Then it was found that it is very efficient and the resistance is very small, which is unmatched by other gas-liquid separation equipment, so it is widely accepted and used in a wide range of applications.

The demister pad is usually placed on the top of the packing tower, which can not only ensure the mass transfer efficiency, but also reduce the board spacing. Demister pad is widely used in vertical cylindrical equipment vapor-liquid separation equipment in chemical, petroleum, pharmaceutical, light industry, metallurgy and other industrial production. It can also be used in desulfurization and other production to remove oil mist, poisonous and toxic gas.

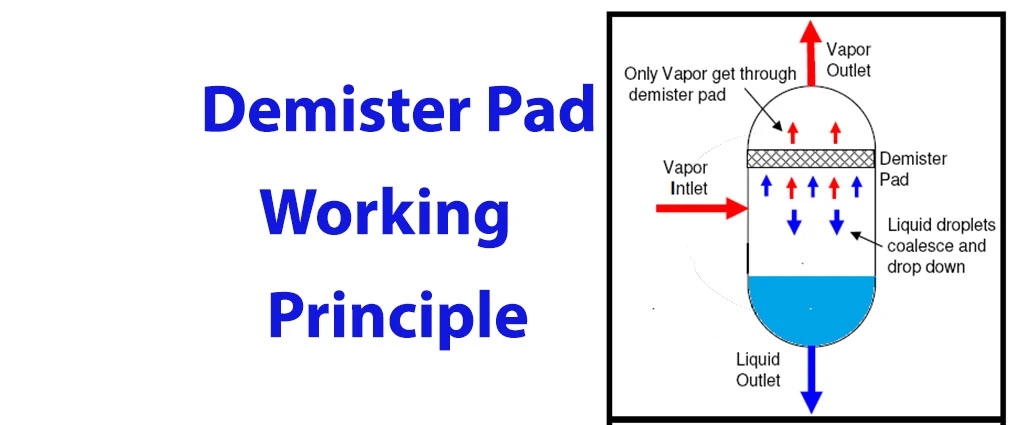

Working principle of demister pad

When the gas with mist rises up at a constant speed and passes through the wire mesh, the rising mist will collide with the mesh filament due to inertia effect and attach to the surface filament. The mist will spread over the surface of the filament and the drop will move along the filaments at the intersection of the two wires. The droplets will grow larger and separate from the filament until the gravity of the droplets outweighs the rising force of the gas and the liquid surface tension force, while leaving very little gas passing through the demister pad. Separating gas into droplets can improve operating conditions, optimize process indicators, reduce equipment corrosion, extend equipment life, increase the amount of processing and recovery of valuable materials. , can protect the environment and reduce air pollution.

How does a demister pad look like

Demisters come in a variety of shapes and sizes and can be installed horizontally or vertically. A typical horizontal demister resembles a large steel wool mesh pad, several feet in diameter and 6 to 12 inches thick.

Fine diameter wires, typically ~0.011 inches in diameter, are interlocked by a knitting operation to form a wire mesh pad with a high free volume (97% to 99+% void fraction) and uniform density . A “tight” mesh (lower void fraction and more dense) is more effective, i.e., it captures smaller diameter liquid droplets versus an “open”, less dense mesh that has a higher void fraction.

The main determinant in the selection of a demister for the issue described here was flooding. In a typical demister installation, a thin demister zone of bubbling liquid (1 or 2 inches in height) develops at the bottom edge of the demister pad. The remaining trap (the active area above the liquid layer) captures the droplets. Liquid droplets collect on the wire mesh and then drain by gravity and accumulate in the dissolution zone, eventually dripping into the liquid pool at the bottom of the vessel. As the velocity/liquid loading increases, the height of the thin dissolution zone of liquid increases and advances into the active zone until carryover of liquid occurs, i.e., the demister is flooded, and the liquid is degassed. Transported into downstream piping and equipment.

How Demister Pads Work

Demister pads are made of woven wire mesh with a very high surface area. When a gas stream containing liquid droplets passes through the demister pad, the droplets collide with the mesh and coalesce into larger droplets. Large droplets are too heavy to be carried with the gas stream, so they fall out of the gas stream and collect at the bottom of the demister pad.

Advantages of Demister Pads

Demister pads have a number of advantages over other methods of removing liquid entrainment from gas streams, including:

- High efficiency at removing small liquid droplets

- Low pressure drop

- Small footprint

- Easy installation and maintenance

Applications of Demister Pads

Demister pads are used in a wide variety of process piping applications, including:

- Distillation towers

- Fractionating columns

- Scrubbers

- Knock-out pots

- Vapor separators

- Compressor intakes

- Turbine intakes

Conclusion

Demister pads are an effective and efficient way to remove liquid blockage from gas streams. They are commonly used in process piping applications to protect downstream equipment from fluid ingress.

Demister pads are used to remove small liquid droplets from a gas stream. They work by aggregating droplets into larger droplets that are too heavy to be carried with the gas stream. Demister pads have several advantages over other methods of removing fluid deposits, including high efficiency, low pressure drop, small footprint, and easy installation and maintenance. They are commonly used in process piping applications such as distillation towers, fractionating columns, scrubbers, knock-out pots, vapor separators, compressor intakes, and turbine intakes.

Read Also

Download Free Piping PDF for Interview Preparation

What is gasket and their types

What is a valve and its types?