What is the full meaning of fitter?

What does “Fitter” mean?

“Foundation of Industrial Training and Technology Resources” is referred to the abbreviation of FITTER. A “Fitter’s” employment mostly entails assembling, installing, and maintaining various mechanical systems or components. Fitters may be employed in a variety of sectors, such as manufacturing, building, engineering, or maintenance.

They frequently read and understand technical drawings or blueprints, and they use hand or power tools to construct or repair parts and precisely align and fit components.

There are quality inspections carried out, and the safe and effective operation of any apparatus or equipment is guaranteed. Fitters frequently work closely with engineers or other experts to guarantee accurate assembly and functioning of machinery or structural components, which greatly enhances the project’s or facility’s overall operational performance.

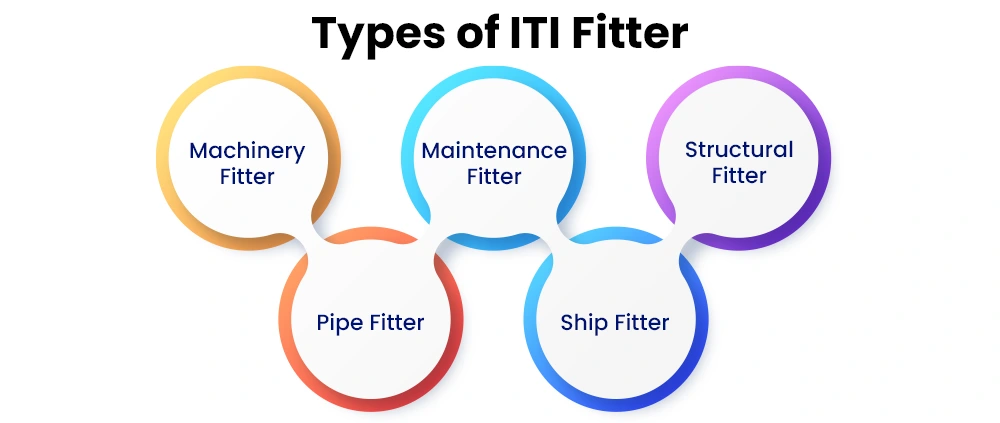

Types of Fitter

The term “Types of Fitter” refers to a variety of sectors, most notably manufacturing, and construction, where workers with specialized knowledge of fitting and assembling parts and components to produce working machines or structures are employed.

Fitters are highly skilled individuals who are tasked with reading and analyzing blueprints, understanding technical drawings, and using a range of equipment and technology to accurately fabricate, assemble, and install components. These individuals deal with a variety of materials, including metal, plastic, and wood. They may specialize in pipefitting, structural fitting, or equipment fitting.

These experts are vital in guaranteeing that the finished product satisfies requirements, functions well, and follows safety guidelines. Their expertise rests in the meticulous fitting, aligning, and adjusting of parts, which makes them indispensable to the building and upkeep of diverse industrial apparatus and infrastructure.

Fitter Examples

- Pipe Fitter: Specialists in the installation, maintenance, and repair of industrial equipment, pipe systems, such as those found in chemical plants, oil refineries, and HVAC systems.

- Mechanical Fitter: Assembles and fits parts of machinery and mechanical equipment to guarantee correct operation. Jobs like assembling engines, conveyor systems, or manufacturing equipment may fall under this category.

- Structural Steel Fitter: Focuses on assembling and installing steel beams, columns, and frames—among other structural components—in structures and infrastructure.

- Maintenance Fitter: In charge of performing regular upkeep, inspections, and repairs on a variety of mechanical systems and equipment in order to guarantee peak efficiency and avoid malfunctions.

- Machine Fitter: specializes in the safe and effective assembly, installation, and maintenance of particular kinds of machinery. Work involving production machinery in manufacturing facilities may fall under this category.

- Welder Fitter: Uses welding techniques to build and attach metal components. Combines fitting experience with welding knowledge. They work on projects involving metal, including machinery and buildings.

These are only a few examples; depending on the sector, particular tools, or job needs, additional specialized positions or variants within the subject of fitting might be discovered. Each sort of fitter needs a different set of skills and knowledge specific to the equipment or systems they work with.

What is the Fitter ITI?

The term “Fitter ITI” is a course offered by the Industrial Training Institute (ITI) that focuses on the trade of “fitter.” This program aims to provide participants with the information and abilities needed to operate in various industries, especially the mechanical and industrial sectors.

The major goal of Fitter ITI is to provide thorough instruction in the assembly, fabrication, maintenance, and repair of machinery and equipment. A wide range of topics are usually included in the curriculum, including welding, metalworking, fitting and assembly procedures, engineering design, workshop science, and calculations. A major part of the course is practical hands-on instruction that enables students to become proficient in handling tools, machinery, and equipment that are frequently seen in industrial settings.

The Fitter ITI program seeks to produce skilled workers who can decipher technical drawings, carry out precise work, diagnose mechanical problems, and guarantee the smooth operation of mechanical systems. Graduates can work as fitters, mechanics, machinists, or maintenance technicians after completing the program, or they can continue their studies in related subjects. With their specialized knowledge and abilities, these professionals can make a major contribution to a variety of sectors.

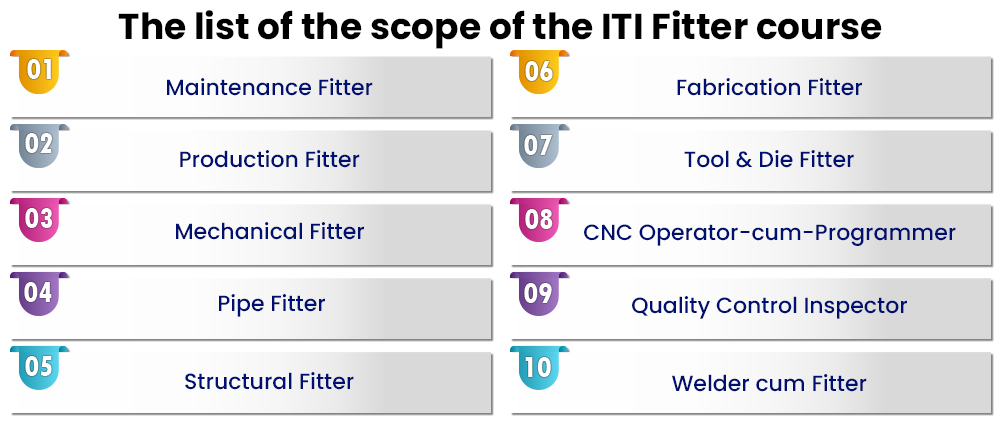

What is the scope of this course?

An ITI Fitter course covers a broad range of prospects in the manufacturing and industrial industries. The Industrial Training Institute, or ITI, provides a Fitter course designed to give specialized knowledge and abilities in the fitting and assembly of different types of machinery.

Students gain an understanding of the principles of interpreting technical drawings as well as precise measuring, cutting, shaping, and assembling metal components during the course. Graduates acquire proficiency in using hand and power tools, comprehending various equipment kinds, and resolving mechanical problems.

This course covers a wide range of businesses, including manufacturing, engineering, construction, and more. Graduates of ITI Fitter programs can work in a variety of industries as fitters, quality control inspectors, machine assemblers, fabricators, and maintenance technicians.

In addition, they can become supervisors or specialize in certain fields like maintenance activities, welding, machining, or CNC operations with experience and ongoing skill development. The degree guarantees a bright professional path and chances for advancement and specialization by providing students with practical skills that are in demand across sectors.

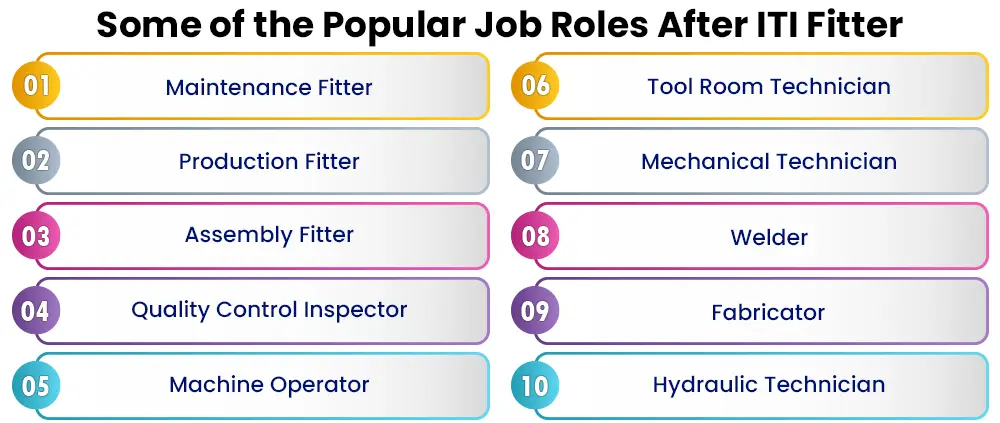

What is the job of the Fitter?

An Industrial Training Institute (ITI) Fitter works in a variety of industrial settings and is responsible for a wide range of vital tasks. An ITI Fitter’s main duties include manufacturing, assembling, and fitting mechanical parts and components to build machinery, equipment, and structures under engineering designs and requirements.

They ensure precision and accuracy in their job by having a thorough grasp of the various tools, machines, and processes needed for cutting, shaping, and aligning metal components. To guarantee smooth functioning, an ITI Fitter also performs routine maintenance, fixes or replaces broken components, and inspects machinery to find flaws or deficiencies.

They are skilled at taking measurements of components’ dimensions using calipers, micrometers, and gauges to make sure they satisfy precise requirements. An ITI Fitter may also participate in the design process, make recommendations for enhancements, and guarantee adherence to safety standards and regulations while working closely with engineers and other team members.

They play a crucial part in the production, upkeep, and repair of machinery in a variety of sectors, demonstrating their indispensable technical knowledge, accuracy, and problem-solving abilities.

What is Fitter in Construction?

A competent expert trained through an Industrial Training Institute (ITI) program with a concentration on fitting jobs within building projects is known as an ITI Fitter in the construction business. Fitters are essential to the assembly, setup, and upkeep of several pieces of equipment and gear used on building projects.

To comprehend the exact requirements for fitting mechanical components, piping, and structural elements, their duties also include reading and interpreting technical schematics, drawings, and specifications. They cut, shape, and connect materials including metal, plastic, and fiberglass using a variety of instruments, including wrenches, drills, grinders, and measuring devices. To preserve structural integrity and performance, ITI Fitters makes sure that the fittings are precisely aligned and fastened.

They also work closely with other tradesmen, such as electricians, carpenters, and welders, to integrate and coordinate their work within the larger building framework.

The position greatly contributes to efficiently completing building projects by requiring accuracy, meticulousness, and a thorough grasp of construction materials and processes.

What is the salary of a Fitter?

This is the common question asked by the most of the people. So an ITI (Industrial Training Institute) Fitter’s pay varies greatly depending on several variables, including region, industry, experience, and particular work duties.

In India, an entry-level ITI fitter should generally budget between ₹10,000 and ₹15,000 per month. However, this number might significantly increase with more experience and knowledge.

ITI Fitters with expertise and experience can make ₹20,000 to ₹40,000 or more per month, particularly in manufacturing, automotive, aerospace, or heavy machinery sectors. Individuals employed in businesses requiring specialized talents or in urban areas may be paid more.

An ITI Fitter’s earning potential can also be greatly impacted by extra abilities in welding, machining, or maintenance, certifications, and the capacity for accurate and efficient work. All things considered, entry-level pay could be low, but with experience, knowledge, and the appropriate sector exposure, there is a good chance of earning more money.

Read Also

Download Free Piping PDF for Interview Preparation

What is gasket and their types

What is a valve and its types?

nuts and bolts specification astm-a193-b7 and a194-2h

Follow us on Instagram – ![]() / sonusinghrefinery

/ sonusinghrefinery

For related pdf & article Visit – https://www.sonusinghyoutube.com

We make videos related oil and gas refinery maintenance and shutdown jobs topic, here we presented some videos please go and check it out. Other Videos playlist you can watch click on below link…

Refinery, Shutdown, Maintenance, Oil & Gas, Piping: ![]() • Refinery, Shutdown, Maintenance, Oil …

• Refinery, Shutdown, Maintenance, Oil …

Piping Related Videos: ![]() • Piping Related Videos

• Piping Related Videos

Complete Heat Exchanger: ![]() • Complete Heat Exchanger

• Complete Heat Exchanger